Lightweight Concrete Floor On Wood Subfloor

For more on instal.

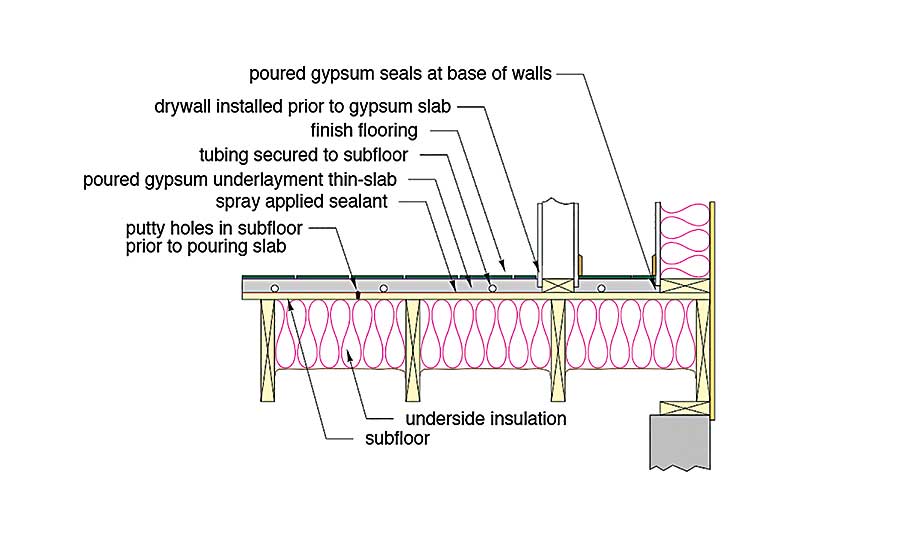

Lightweight concrete floor on wood subfloor. Make sure the concrete is well bonded to the sub floor. Duraamen s param 5500 goes on thin in a 3 8 to 1 2 thick application. This includes lightweight wood concrete slab modular lightweight concrete floor system and precast concrete lightweight concrete floor. The floor is rated to accomodate 1 1 2 of concrete to encase the pex tubing.

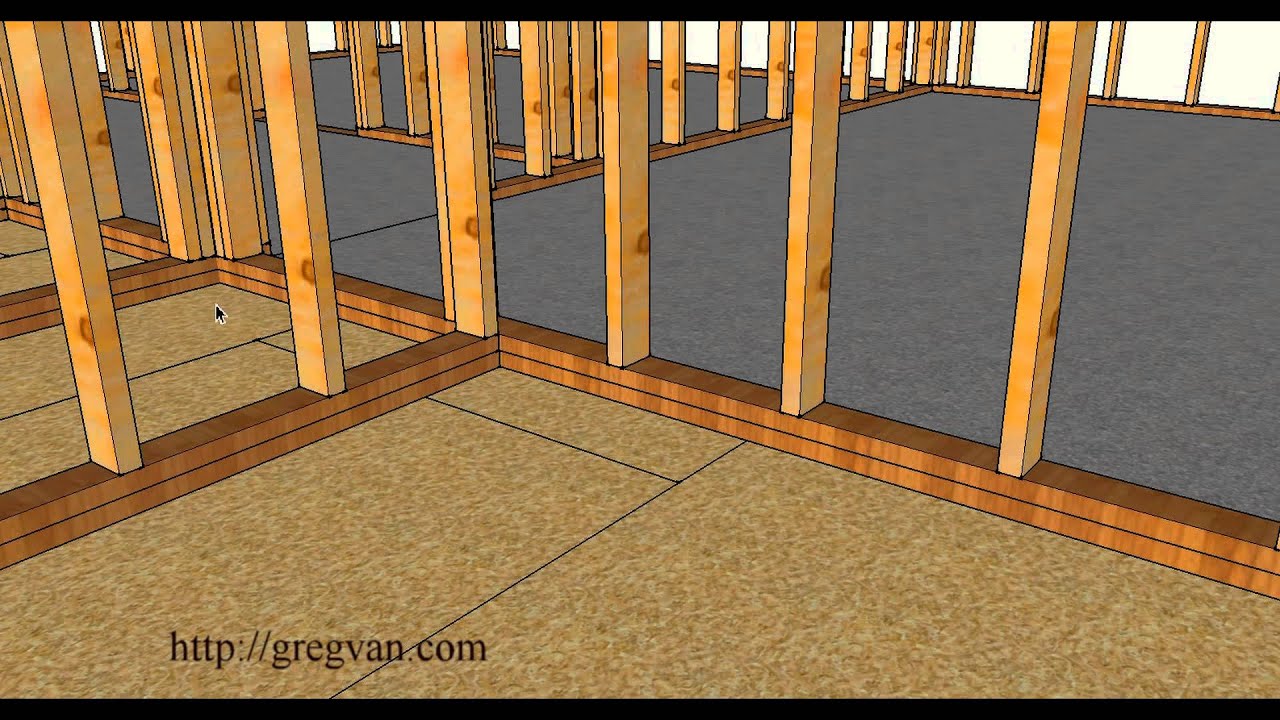

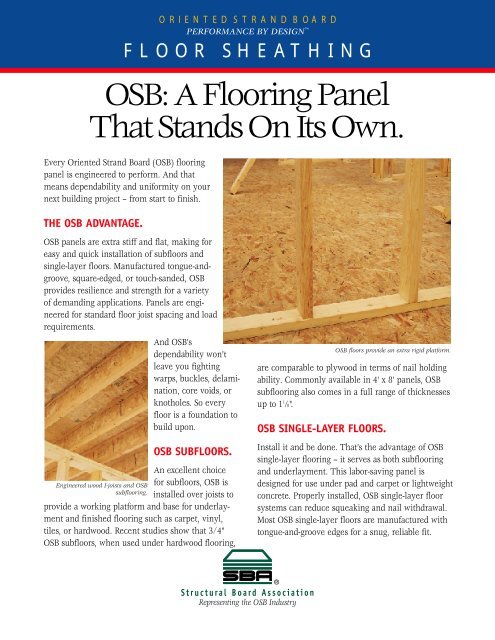

It lays down ultra flat. Since there are no lightweight concrete contractors in our area we are going to place the concrete ourselves. I have used 3 4 tongue and groove plywood for the subfloor. Many manufacturers of hardwood floorboards will not honor warranties if the flooring is installed on a lightweight concrete subfloor.

If it leaves an indentation it is probably lightweight concrete. For the second story a foamed type of lightweight concrete is being used over plywood for sound absorption between floors. Metal lath stapled over plywood substrate the installation of calcium aluminate cement based self leveling concrete param 5500 along with expanded metal lath for reinforcement is a successful fast track method to convert a plywood subfloor into a beautiful concrete floor. Lightweight wood concrete slab.

Please send us information regarding the proper chemical to use to achieve the proper mix for the lightweight concrete. With some judicious control joints we only had a few cracks. As with on grade concrete sub floors make sure the concrete is clean flat to. Find out how concrete floors are installed over a wood sub floor.

I am researching the use of icf style forms that would allow a free span from wall to wall and eliminate the wood floor structure all together. An example is lite deck which costs around 3 25 sqft of floor surface for the form. We had a similar concrete floor with radiant tubing and the wire mesh attached to spacers just floated over the top of the tubing. Tips on how to protect the floor from water leakage and moisture issues.

I could call in a contractor to pour gypcrete over the pex at a cost of about 4000. They would be stained and sealed to create the finished floor. The concrete was specified to reach 3 500 psi at 28 days with a water cementitious ratio of 0 45 and a max. Since lightweight concrete is more prone to cracking than traditional concrete it can lead to problems when used with hardwood floors.

I am exploring concrete floors on the main level over basement to get some mass into the space. Check for hollow spots cracks and loose areas. Some of these floor systems are modifications of the aforementioned lightweight systems. Other lightweight floor systems.