Lightweight Fiberglass Mat

Fiberglass is a strong and lightweight reinforcement used in composites.

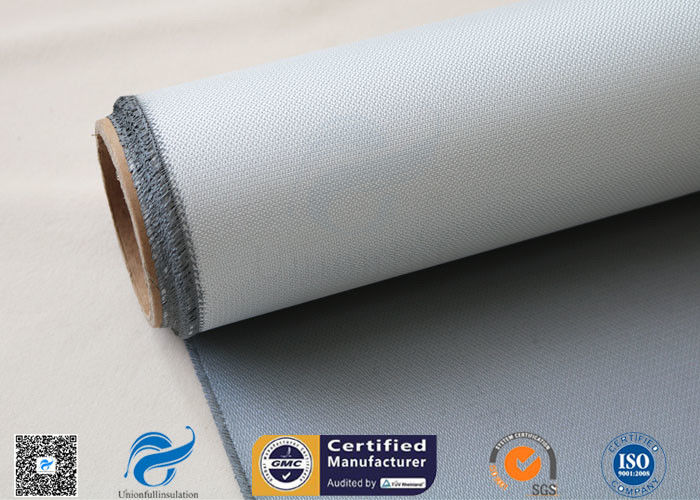

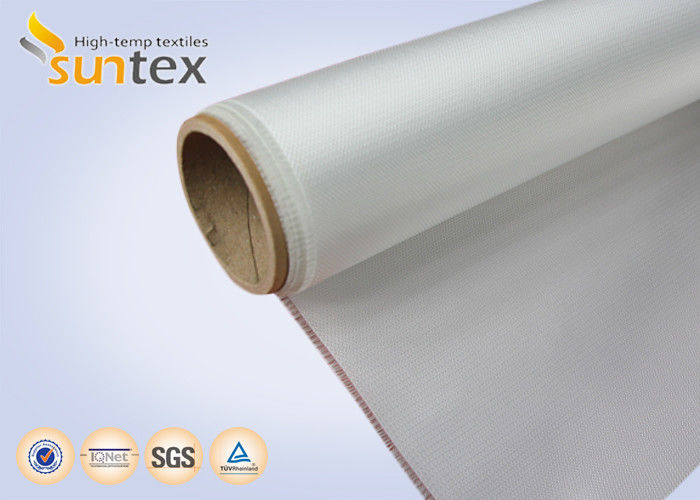

Lightweight fiberglass mat. This lightweight fiberglass cloth is used on applications where a very thin laminate is desired. It was of particular interest to the aviation industry. For instance for items such as shingles a massive sheet of a fiberglass and resin compound is manufactured and then cut by machine. Fiberglass cloth also known as fiberglass fabric is an excellent choice when you are looking for a strong light weight part.

Fiberglass can be mass produced in mats or sheets. Our company supply lightweight fiberglass cloth white fiberglass cloth and 7628 fiberglass cloth. Frp is sometimes called composite because it s made of a combination of materials that work together for even stronger performance. Fiberglass reinforced polymer is a strong lightweight building material that resists corrosion.

Mat is used primarily for building thickness and stiffness into fiberglass layups. Fiberglass mat is one of the most popular forms of reinforcement for non structural applications. They re affordable easy to use and deliver excellent strength low weight and solid cosmetics. Lightweight fiberglass bridge by e t.

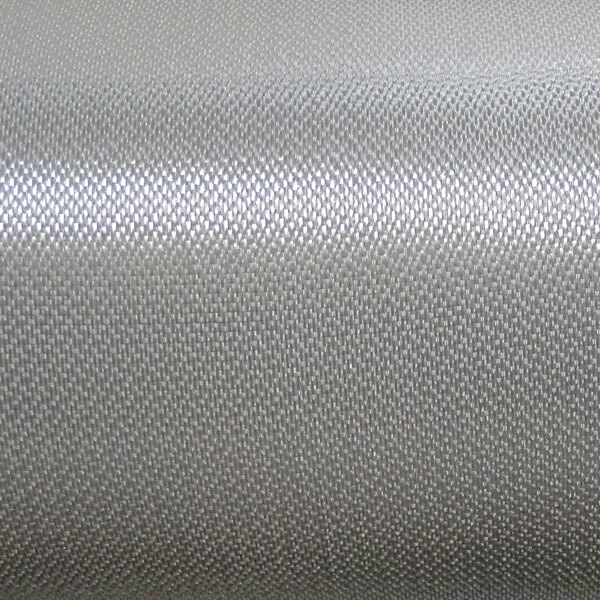

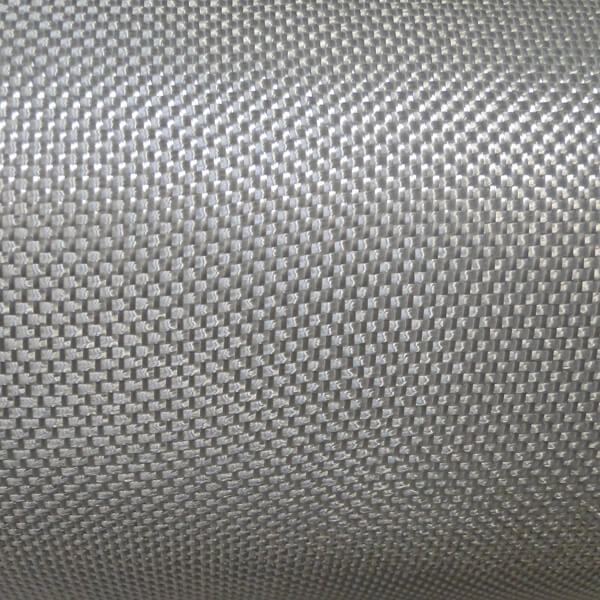

Fiberglass is an immensely versatile material due to its lightweight inherent strength weather resistant finish and variety of surface textures. This is a very popular hobby fabric. Choose from a broad product offering each fabric with unique fabric characteristics to suit your part. It s inexpensive easy to use and can quickly build thickness into parts molds or even a repair.

All of our fabrics must be used with a resin system polyester vinyl ester or epoxy to create a composite part the fiberglass is what gives any part it s strength. Fiberglass fabrics are in stock for same day shipment. It features randomly oriented strands throughout that effectively hide print through of heavier fabrics and create an equal stiffness in all directions for molds and parts. It is used in a great variety of applications.

Mat resists print through where the weave of roving shows in the outer layer of the hull but it also soaks up a tremendous amount of resin and is low in strength for its weight. The development of fiber reinforced plastic for commercial use was extensively researched in the 1930s. By peter sturdivant cdw contributing editor. This is one of the advances in reinforcing materials.

Fiberglass bridge project location. Creative pultrusions and e t. Used on model airplanes. Posted and updated 3 6 18.

Washburne state park oregon manufacturer. Very delicate use vinyl or latex gloves while handling the cloth.