Low Emissivity Ceramic Coating

Low weight less than 0 001 gm sq ft lowest emissivity available in a spray on lo mit ii max 0 145 high temperature tolerance to 1000 f 538 c excellent adhesion and flexibility even on plastics and rubber.

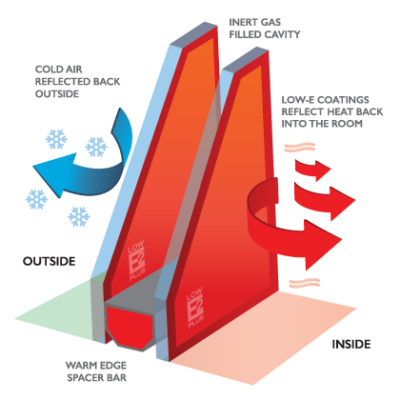

Low emissivity ceramic coating. Main coatings and glazing options that best suit australian conditions. This is where low emissivity or low e glass coatings come into play. When justifying the additional cost it is natural to ask how exactly this invisible coating is going to help save energy and increase comfort and what are the key factors to be aware of when choosing them. The performance of low emissivity coatings requires the use of large tir suppressing pigments when compared with conventional colored pigments that would not normally be used for conventional coatings.

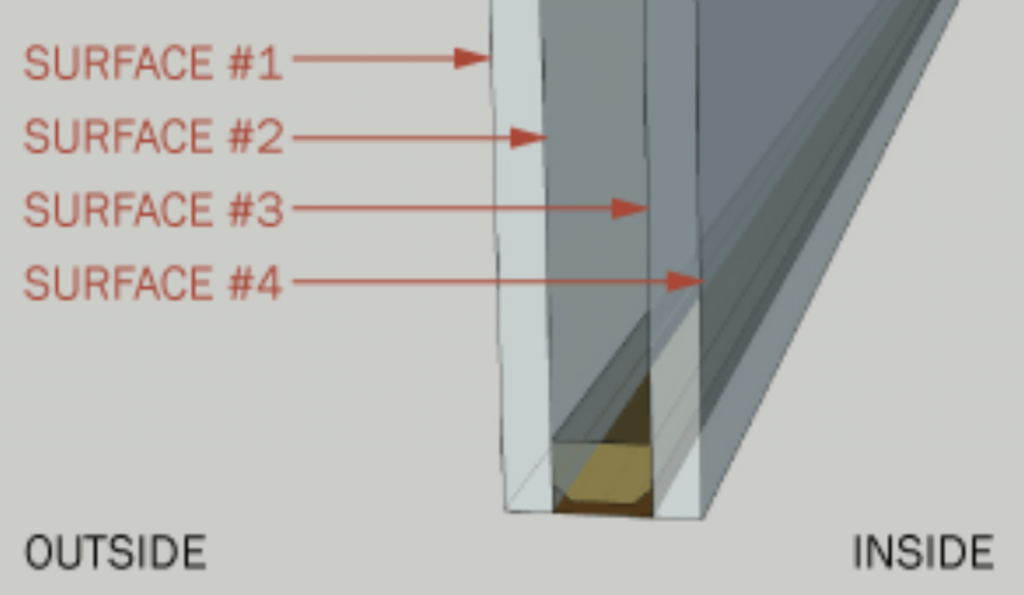

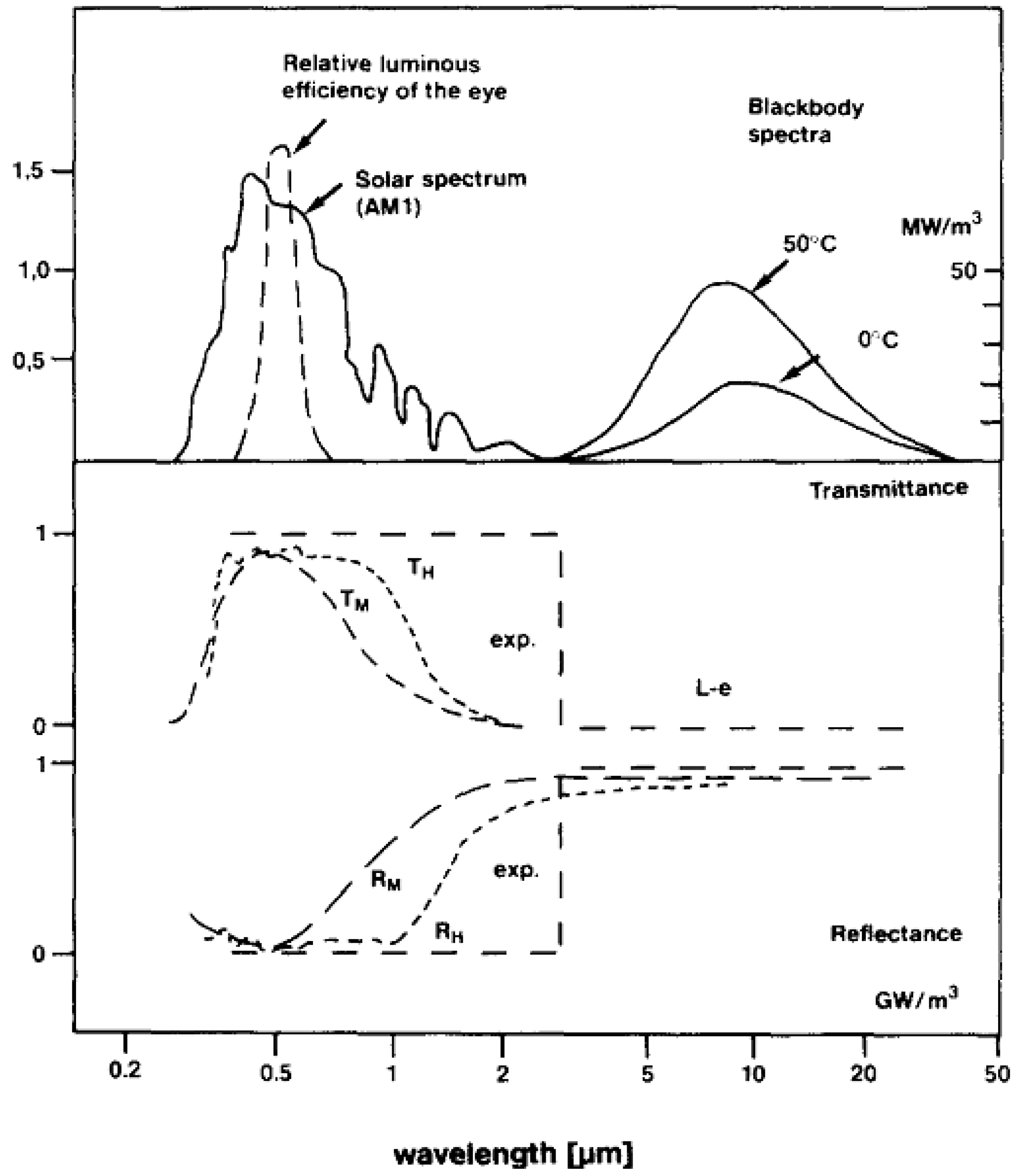

Low e glass has a microscopically thin transparent coating it is much thinner than a human hair that reflects long wave infrared energy or heat. Low emissivity coatings essentially work by interacting with radiation in the two regions that windows are exposed to. Low emissivity coatings are common place in high performance window assemblies and the benefits to including them are quite large. High temperature version of ultra ve 17.

The lo mit coatings have many unique properties that make them ideal for a wide variety of industrial applications. The first being the solar region short wavelength radiation emitted from sun and the other being the room temperature region long wavelength radiation. Used to control ir reflectance on aluminum. When the interior heat energy tries to.

Coating to control thermal radiation with solar absorbance and emittance applications.