Low Profile Options For Laminate Beam Applications

Hpls are the most commonly used laminates.

Low profile options for laminate beam applications. Compare click to add item 5 1 4 x 13 3 4 treated glulam beam to the compare list add to list click to add item 5 1 4 x 13 3 4 treated glulam beam to your list sku 1064170. Shelf includes decking and 2 left to right beams. Low profile 1 height single rivet beams to maximize storage space. Laminate is manufactured one of two ways.

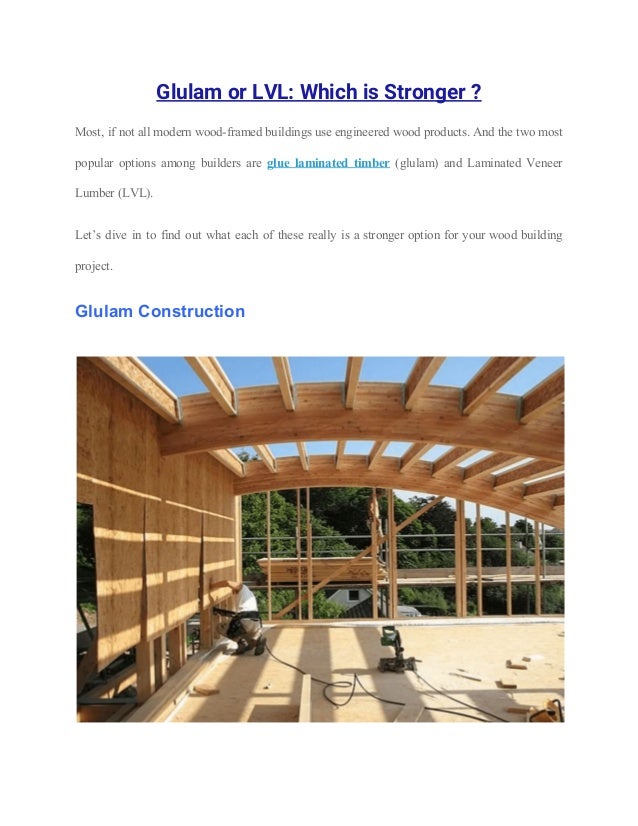

A regular laminate sheets. It s available in hundreds of designs it s low maintenance it s heat and impact resistant and it offers high value for the investment. Some even use glulam for long span roof beams and heavily loaded floor beams. One can find stock beams that come in 60 foot lengths and they are used for spans upward of 20 24 and even 28 feet or higher.

With laminate board thickness of thickness to provide a strong and durable shelf surface. My wife wants it removed. Types of laminates based on thickness. After the glue up except for cleaning excess adhesive and finishing the sides of the beam the work is done.

A nice approach to use when building tapered beams or beams with tapered ends is to taper individual plies prior to laminating. However no matter how accurately and diligently a profile. Another disadvantage is their low saturation and damage threshold levels. In order to minimize interference and provide the most accurate laser beam profile the protective window is removed and the cameras are shipped with an nd filter and a protective cap premounted on them.

B low pressure laminate lpl. Both the cameras are available in the 640x480 array low resolution or the 1600x1200 array high resolution versions. Beam propagation beam profilers measure the spatial intensity distribution of a laser beam. These shelves are recommended for standard to heavy duty applications.

Laminate has many features that account for its widespread use. In low pressure laminate decorative paper is soaked in melamine resins and dried naturally and then it will bonded over mdf hdf or particle board with heat activated glue and laminator having a heat rollers for consistent and fine bond. We have had two contractors out to give us an. A span of about 15 feet is supported by the beam.

The problem is that a post is holding up the beam that supports the roof. Some special considerations should be made when. Under high pressure or low pressure. It is tough to taper a laminated beam with saws and planes after it is laminated.

Glulams is strong and dimensionally stable so you can use it for a variety of applications. In low pressure laminates the decorative paper is soaked in melamine resin and the laminated paper is then directly bonded to particle board or fiber board mdf and hdf at low pressure.