M2 Tool Steel Equivalent

1 3343 is the equivalent numeric designation for m2 material identified in iso 4957.

M2 tool steel equivalent. M2 high speed steel wolfram tungsten molybdenum vanadium based well known standard high speed steel with high wear resistance. Tool steel comparison chart compare popular tool steel grades a2 m2 d2 s7 o1 using the chart below. It is usually used to manufacture a variety of tools such as drill bits taps and reamers. Cutting tools twist drills milling cutters stamping and cutting tools broaches forming tools woodworking tools cold extrusion press tools.

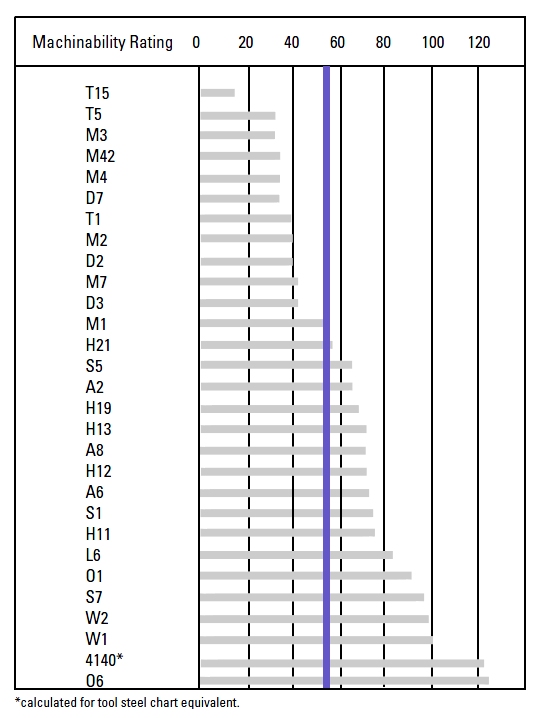

M7 m7 is used for making heavier construction drills where flexibility and extended drill life are equally important. The h ss m2 chemical composition gives a good combination of well balanced toughness wear resistance and red hardness properties. If you are interested in the past and current steel trade volumes in various steel products around the globe this section is just for you. Compare grades using mechanical properties including abrasion resistance toughness size stability machinability and grindability.

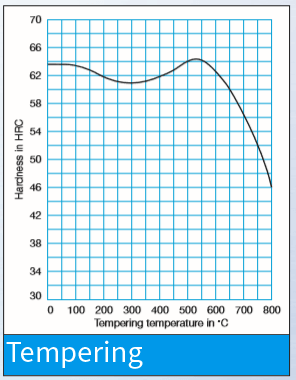

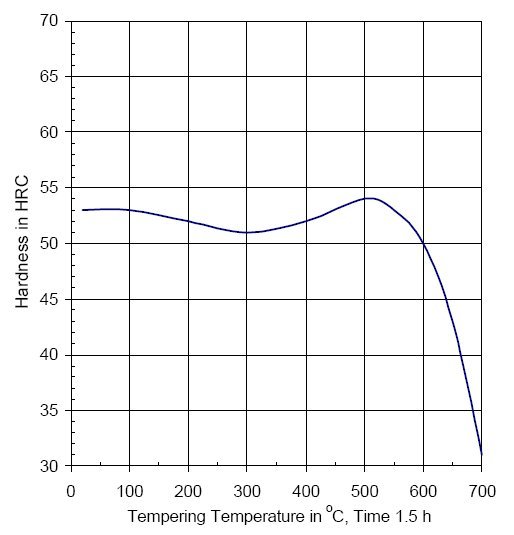

It is easy to overheat control the quenching heating temperature is necessary and the heat treatment protection requirements are strict. Hardened for increased abrasion and impact resistance. It shows a high toughness and high hardness applications. Events events our major market leading conferences and events offer optimum networking opportunities to all participants while adding great value to their business.

M2 high speed tool steel is tungsten molybdenum high speed steel with a well balanced carbon composition and high toughness. Grind your own lathe tool blanks. M2 tool steel bars. Hs 6 5 2 1 3343 s600 steel e m2 rex m2 skh 51 p6m5 6 6 m2 tool steel.

Hardened high speed m2 tool steel sheets. M2 tool steel is generally suitable for use in applications specified for t1 high speed steel. Grind these hardened steel blanks to the size and shape you need. M2 high speed steel is by far the most popular high speed steel replacing t1 in most applications because of its superior properties such as its bending strength toughness and thermo plasticity all of which are higher than t1 by 50.

Hss grade steel m2 is a medium alloyed high speed steel which has good machinability. Drill bits reamers taps gear cutters lathe tools broaches boring tools forming rolls inserts punches milling cutters and end mills. Widely used for cutting tools such as twist drills taps milling. These bars are precision ground to a tight thickness tolerance.

Aisi m2 tool steel is molybdenum based high speed steel in tungsten molybdenum series.