M2 Tool Steel Mechanical Properties

Compare popular tool steel grades a2 m2 d2 s7 o1 using the chart below.

M2 tool steel mechanical properties. This grade is characterized by balanced combination of abrasion resistance toughness and good red hardness. Widely used for cutting tools such as twist drills taps milling. Tensile yield strengths and ductilities for some of the plain carbon and low alloy steels are given in the following mechanical properties of steel chart. M2 tool steels are annealed at 1204 c 2200 f and cooled at 72 c 162 f per hour or even less.

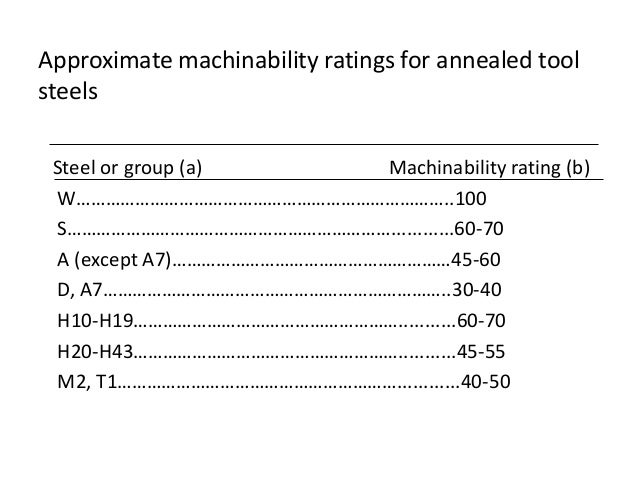

Astm m2 round bar astm m2 flat bar astm m2 hollow bar astm m2 tube pipe astm m2 sheet plate astm m2 strip coil astm m2 wire astm m2 forging astm m2 tube pipe tel 86 13880247006. Tool die steels inc. Hss grade steel m2 is a medium alloyed high speed steel which has good machinability. What is m2 tool steel.

Yield strength tensile strength and ductility values for steels at room temperature. M2 high speed steel. Tensile yield strength of steel chart. World wide the m2 type is by far the most popular high speed steel having replaced t1 high speed in most applications because of its superior properties and relative economy.

M2 high speed steel m2 is a tungsten molybdenum high speed steel with a well balanced composition suitable for a wide variety of applications. Finally m2 steels are hardened by heat treatment and quenching. Tensile strength elong. Stainless steel special steel compressor blading turbine blading superalloy supplier.

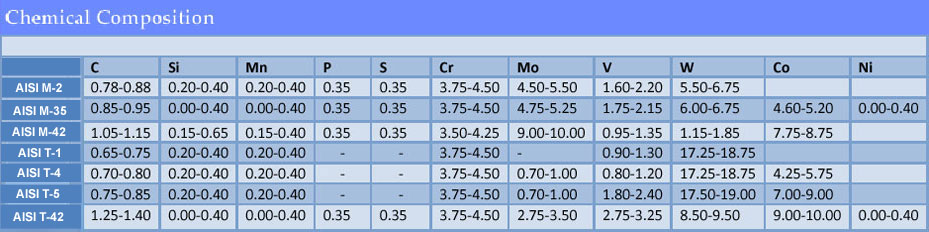

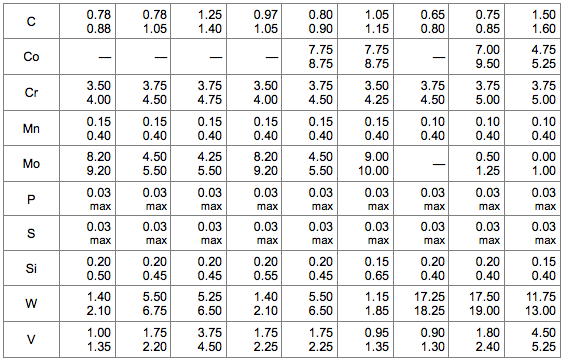

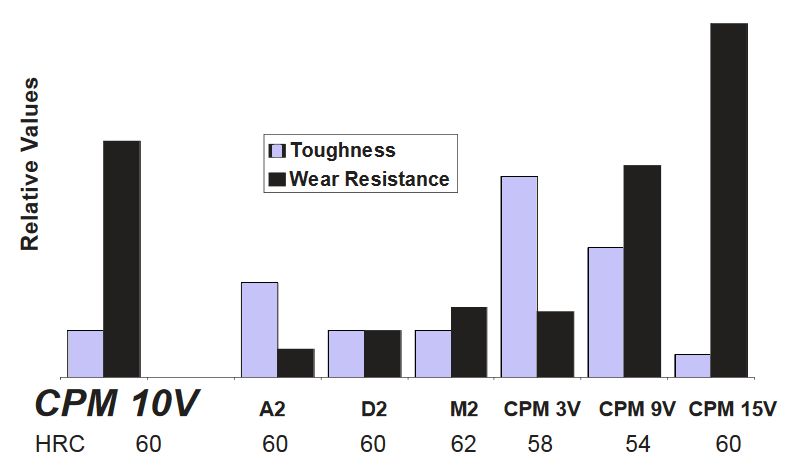

M2 steel composition m2 tool steel m2 tool steel properties tool m2 tool steel supplier m2 tool steel machinability m2 tool steel hardness m2 grade steel. The h ss m2 chemical composition gives a good combination of well balanced toughness wear resistance and red hardness properties. A2 tool steel is an air hardening cold work chromium alloy die steel that is preferable to o1 tool steel in applications requiring greater size stability machinability and safer hardening. M2 steels are tempered at 552 c 1025 f to obtain rockwell c hardness from 60 to 65.

M2 tool steel is a general purpose molybdenum high speed steel. The wear resistance properties and cost place a2 between that of o1 and d2 tool steel making it a good all purpose grade for many applications. Usa astm m2 molybdenum series high speed tool steel and m2 mechanical properties chemical element cross reference datasheet. Compare grades using mechanical properties including abrasion resistance toughness size stability machinability and grindability.

M2 high speed steel is by far the most popular high speed steel replacing t1 in most applications because of its superior properties such as its bending strength toughness and thermo plasticity all of which are higher than t1 by 50.