M4 Tool Steel Compressive Strength

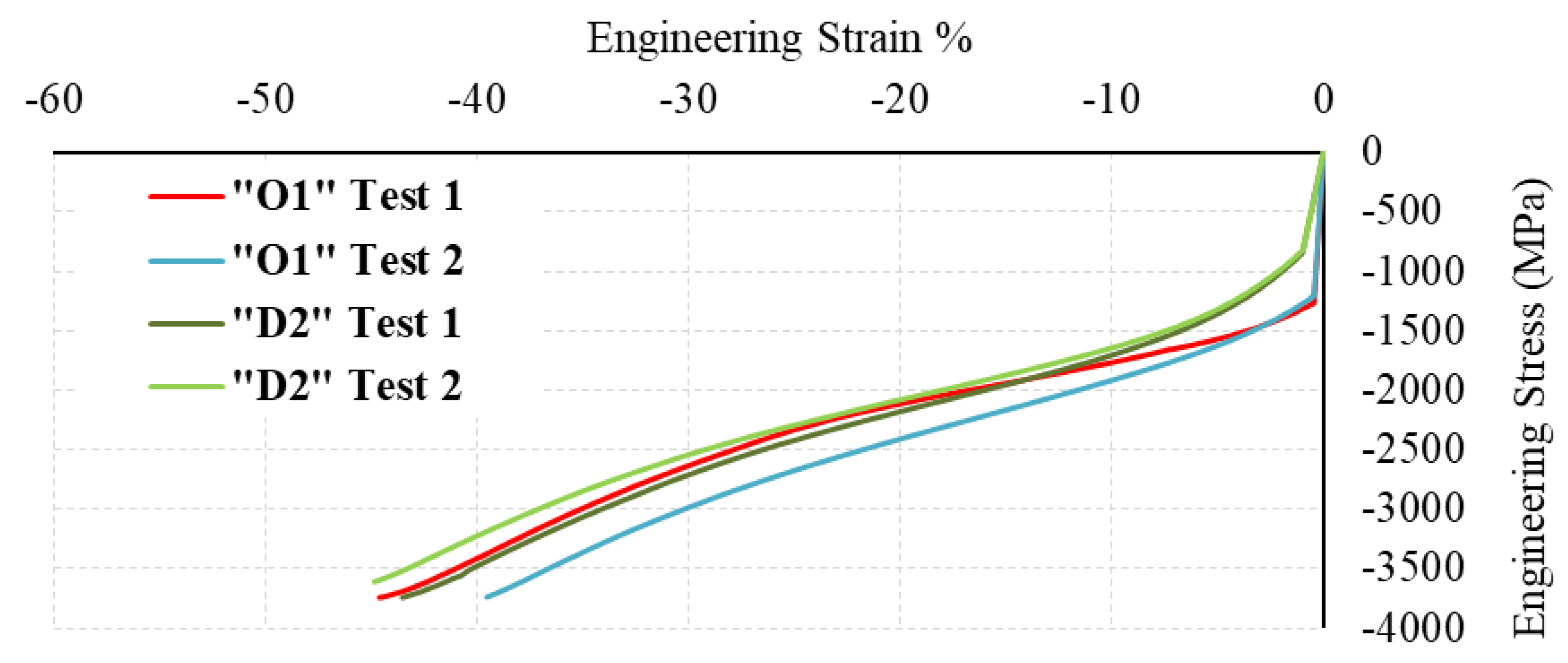

Hardness vs compressive yield strength.

M4 tool steel compressive strength. M2 tool steels are annealed at 1204 c 2200 f and cooled at 72 c 162 f per hour or even less. As a result dozens of tool steel types exist. A large volume of vanadium carbides provides the high wear resistance. However the aisi sae tool steel code categorizes tool steels based on basic application and material characteristics.

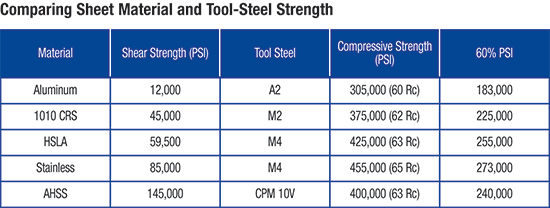

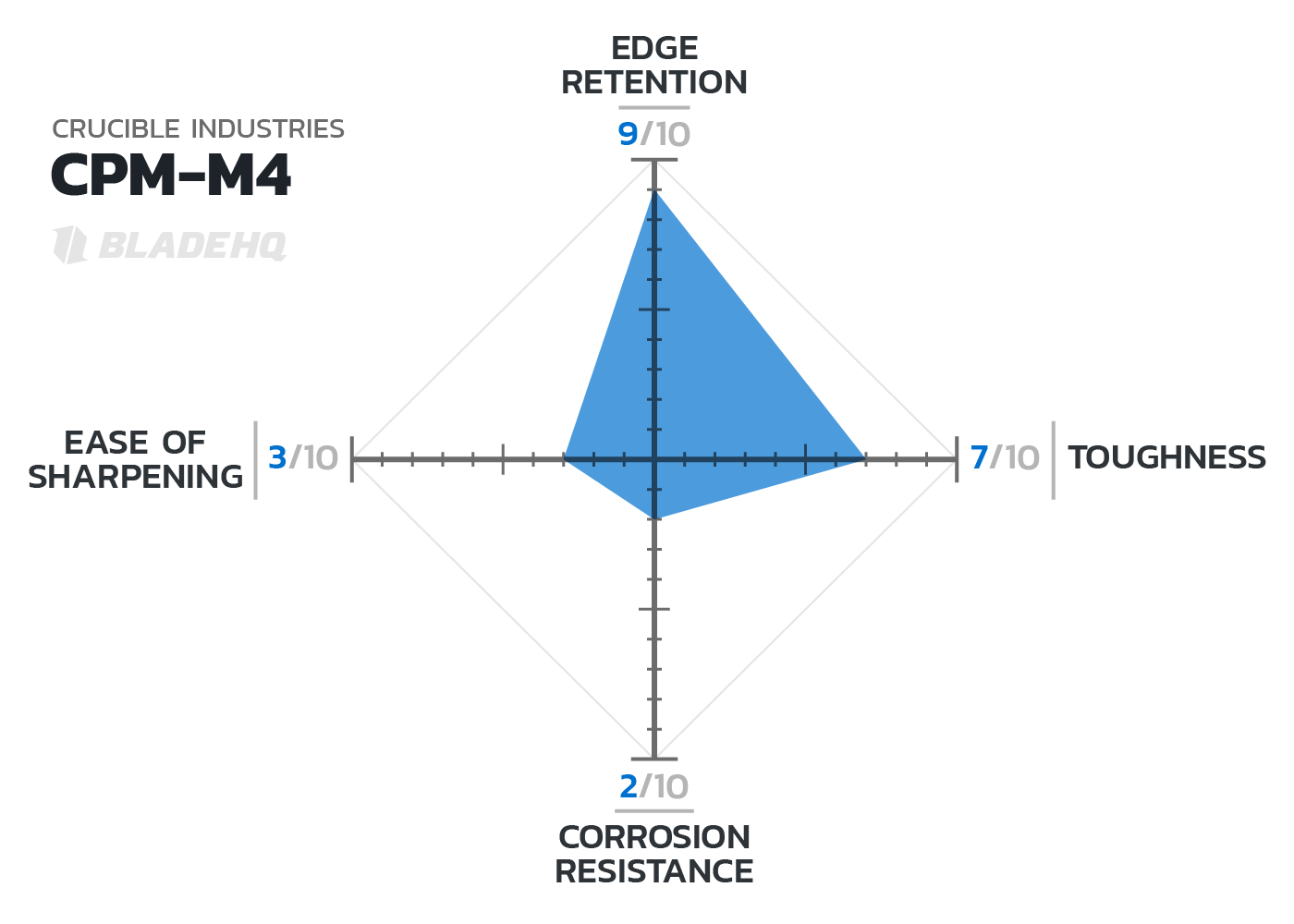

A2 d2 and m4. The high carbon content enables m4 steel to be hardened in excess of 65hrc. It is a measurement of the maximum load an item can withstand before deforming or before a catastrophic failure occurs. Compressive strength is a little known and often overlooked characteristic of tool steels.

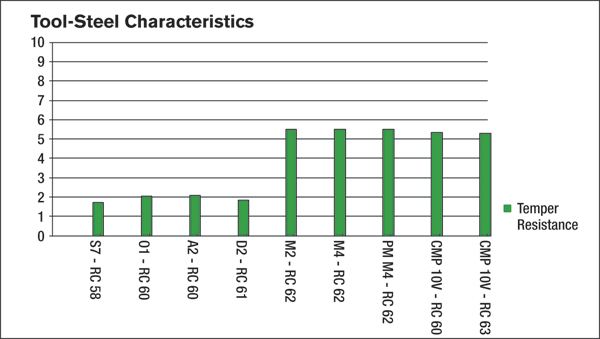

Hs 6 5 4 e m4 skh 54 stark. They are alloy content and tool steel hardness. The specific properties of s7 d2 and a2 tool steels which are among the most popular in industrial and manufacturing applications today are discussed in further detail below. Ideally tool steels would contain as much carbide volume as needed for the desired wear performance.

M2 tool steels are pre heated prior to hardening at 2610 c 4730 f followed by rapid heating from 2610 c 4730 f to 3960 c 7160 f. Cpm rex m4 hc high speed steel is an extremely versatile high speed steel that provides a unique combination of high wear resistance with high impact toughness and transverse bend strength. The high impact toughness and high transverse bend strength are results of the fine grain. In fact solid carbide tooling is typically 85 or 90 tungsten carbide particles in a matrix of 10 or 15 cobalt to hold them together.

Sbsm high speed steel properties comparison. Cpm rex m4 hc powder metal high speed steel. However the high hardness and high vanadium carbide content make it more difficult to grind after heat treatment compared to m2 and other high speed steels. Use it for punches dies and high speed cutting tools.

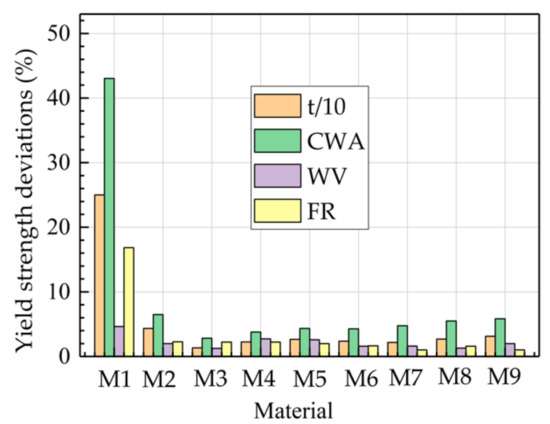

Pm steels have excellent grindability vs conventional steels. Pm m4 high speed tool steel is an extremely versatile high speed steel that provides a unique combination of high wear resistance from the large volume of vanadium carbides with high impact toughness and transverse bend strength which are results of the fine grain size small carbides and superior. Pm m4 is a molybdenum tungsten high speed steel produced using the pm powdered metal steel making process. Griggs steel color code.

Pm m4 high speed steel. Griggs steel offers the following powder metal high speed steels. These rods are decarb free for a uniform surface that will consistently accept heat treating. It is comparable to cpm rex m4.

The grade has an excellent balance of toughness and wear resistance making it ideal for cutting tools and for cold work tooling. These steels are then cooled for 3 to 5 min and quenched in air salt bath or oil. Chemically the microscopic carbide.