Manufacturing Process Of Mild Steel Ingots

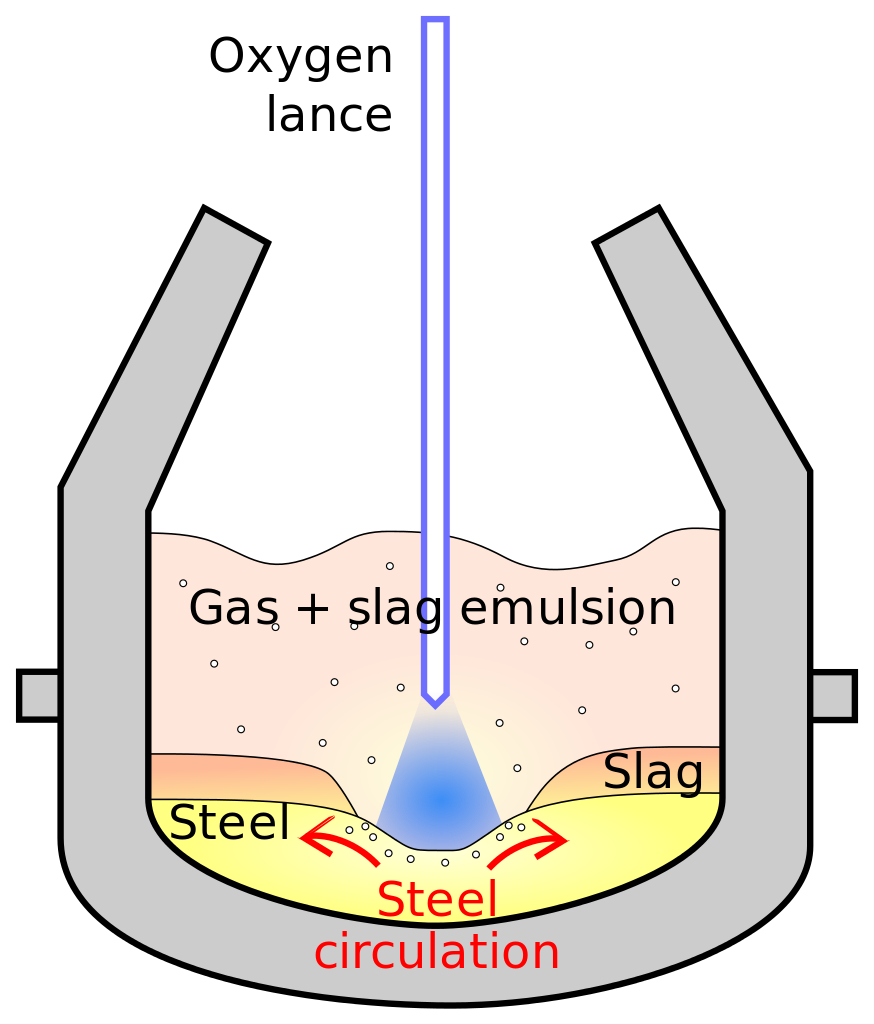

After the steel in the ladle has cooled to the desired temperature the ladle is moved by a traveling crane to either a pouring platform for ingot production or to a continuous caster.

Manufacturing process of mild steel ingots. Scrap from open market imported scrap from actual importer sponge iron from the manufacturers and these materials once reach the plant the quality is tested and after getting satisfied unload the material in the stock yard. 8952 95 specification of steel ingots blooms and billets for production of mild steel wire rods for general engineering purposes. Premelts plays an important role in steel plants producing high quality and stainless steels. Low carbon steel or mild steel.

Get here lists of mild steel ingot ms ingot manufacturers suppliers and exporters. Full detail on production of mild steel ingots from iron ore manufacturing plant cost plant design manufacturing project suppliers manufacturing process analysis report machinery and much more detail to start your industry. The induction furnace as a complimentary aggregate for i e. Mild steel ingots ask price to manufacture mild steel ingots the company purchase m s.

Enough oxygen combining elements are added to the melt that the formation of metal oxides eats up all of the oxygen preventing the development of gas. Ingots may be square rectangular or round and weigh anywhere from a few hundred pounds to 40 tons. Killed steel is produced by the full oxidation of the metal melt. Mild steel is also considered low carbon steel as it is defined as having a low carbon content of 0 05 0 25.

These shown ms ingot manufacturing companies are known for good quality products at low price. Our company is targeting to be amongst prominent mild steel ingots manufacturers in india. Our products are widely acceptable because of its quality control assurance and use of fine raw materials. The semi killed manufacturing process is an economical method of creating steel ingots.

Scrap from open market imported scrap from actual importer sponge iron from the manufacturers and these materials once reach the plant the quality is tested and after getting satisfied unload the material in the stock yard. To manufacture mild steel ingots the company purchase m s. The most commonly used ingot mould sizes for ingot production are 3 x4 x60 3 x4 x60. Mild steel is ductile highly formable and can be used for automobile body parts plates and wire products.

Low carbon steel has 0 04 0 3 carbon content and is the most common grade of carbon steel.

.jpg)